Cooling Systems

Slaughterhouse Cold Room Storage | Meat Chilling, Freezing & Processing Systems

Teknotes Group designs and manufactures high-performance cold room storage systems for slaughterhouses and meat processing plants, including insulated hygienic panels, industrial cold room doors, carcass storage rails, shelving units, chilling tunnels, shock-freezing rooms, and complete freezing solutions optimized for modern meat production facilities.

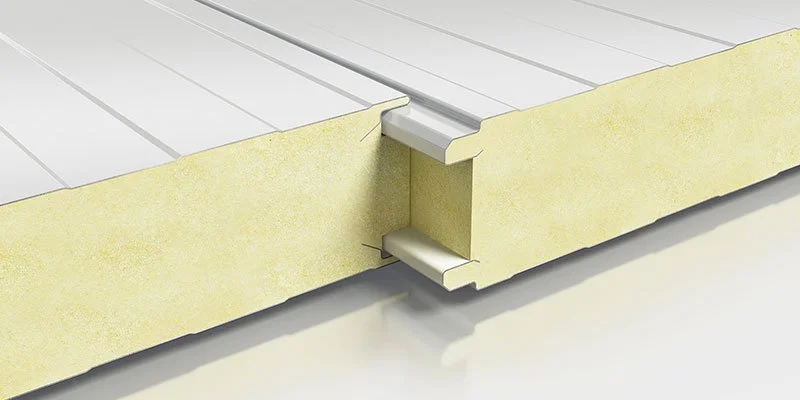

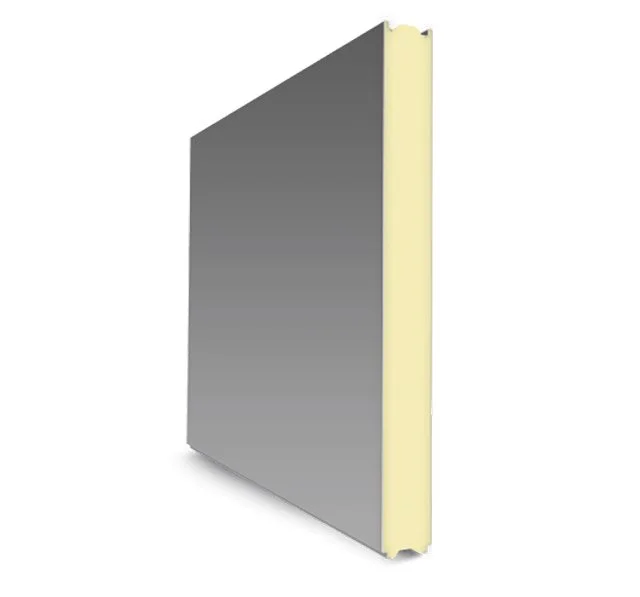

Slaughterhouse Cold Room Panels – Polyurethane Injected Insulated Wall Systems

In slaughterhouses, polyurethane-injected cold room wall panels are produced with a density of 40–42 kg/m³, injected between galvanized, polyester-coated, ribbed steel sheets. While polyester coating is standard, optional surface materials include PVC, CrNi stainless steel, Plastisol, or galvanized sheet for enhanced durability and hygiene.

Thanks to the eccentric locking mechanism, panels interlock securely during installation, ensuring excellent insulation performance, minimum heat transfer, and maximum hygiene inside slaughterhouse cold rooms. These insulated panels provide reliable and long-lasting meat storage conditions for modern processing facilities.

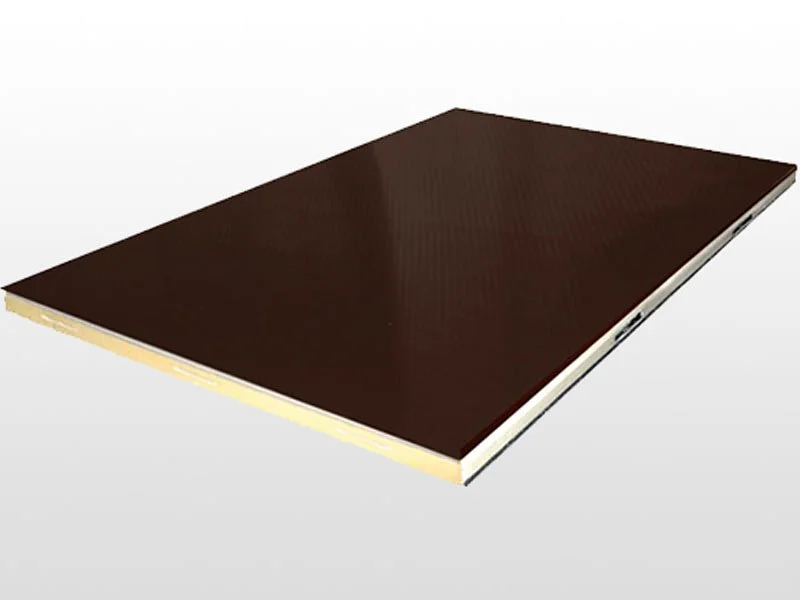

Slaughterhouse Cold Room Floor Panels

In slaughterhouse cold rooms, floor panels are manufactured with a 10 mm slip-resistant patterned plywood on the upper surface and a 0.50 mm galvanized polyester-coated steel sheet on the lower surface as standard. Upon request, the upper surface can also be produced with 0.5 mm CrNi stainless-steel sheet laminated on OSB for enhanced durability and hygiene.

These floor panels offer a load-bearing capacity of 1500 kg/m² (static load) and 200 kg/m² (live load). They are produced in a fixed width of 1110 mm, with thickness options of 50–80–100–150–200 mm, and lengths up to 13 meters.

Thanks to the eccentric locking mechanism, the panels interlock securely during installation, providing excellent thermal insulation, minimum heat transfer in slaughterhouse cold rooms, and a hygienic, long-lasting flooring solution for meat processing facilities.

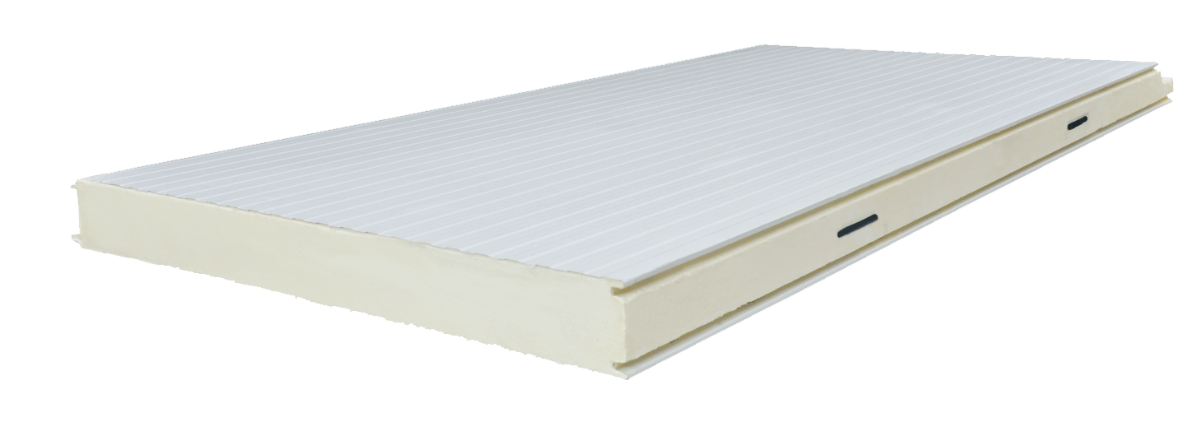

Slaughterhouse Cold Room Ceiling Panels

Cold room ceiling panels for slaughterhouses are manufactured using polyurethane injection at a density of 40–42 kg/m³, injected between two galvanized, polyester-coated, ribbed steel sheets.

The surface material is not limited to polyester; upon request, panels can also be produced with PVC, CrNi stainless steel, Plastisol, or galvanized sheet, depending on the required hygiene and durability level.

With the eccentric locking mechanism, the ceiling panels interlock securely during installation, ensuring minimum heat transfer, superior insulation performance, and hygienic storage conditions in slaughterhouse cold rooms.

Cooling Devices for Slaughterhouses & Cold Rooms

HERMETIC SPLIT TYPE

Split-type hermetic condenser units are ideal for cold rooms and corridor cooling applications with low capacity requirements. Their compact design ensures easy installation and maintenance, while sound pressure levels remain at a minimum.

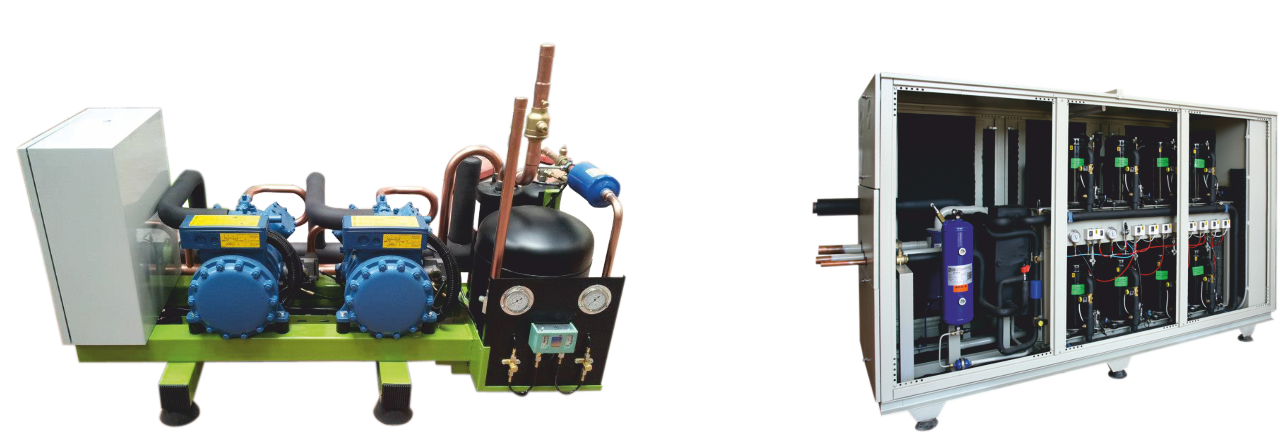

INDUSTRIAL TYPE COOLING

Industrial-type condenser units are designed for medium and high-capacity cooling requirements in industrial facilities. Their compact body ensures easy installation, while the use of high-capacity compressors provides superior efficiency.

SCROLL SPLIT TYPE

Scroll-type split condenser units offer low noise and vibration levels, making them highly suitable for supermarket and market refrigeration. With high energy efficiency, these units ensure minimum energy consumption during operation.

SHOCK COOLING UNITS

Shock cooling units are ideal for situations requiring rapid freezing or pre-freezing. These units reduce the product temperature below freezing levels in a short period and are suitable for both short-term and long-term frozen storage.

SEMI HERMETIC SPLIT TYPE

Semi-hermetic split condenser units are designed for low and medium-capacity cooling needs. Offering a wide selection of capacity ranges, they are suitable for various industrial cold room applications.

CENTRAL COOLING SYSTEMS

Central cooling systems are suitable for industrial cold storage and supermarkets with high-capacity cooling demands. They are available with separate condensers or fully integrated systems. Capacity options include 3, 4, and 5 compressors for semi-hermetic models, and 4 to 12 compressors for scroll models.

Sliding Cold Room Door

High Energy Saving with Durable Aluminum Profile

CTP composite door construction

1.5 mm AMB (antimicrobial) FRP, painted sheet metal or stainless-steel surface options

EPDM rubber–based sealing system for superior insulation

Seamless surface when using 1.5 mm AMB (antimicrobial) FRP

Custom color options available for the door leaf

Door leaf and frame are manufactured from anodized aluminum, preventing heat transfer

Door leaf insulated with high-pressure polyurethane injection (42 kg/m³ density)

220 V, 25 W/m silicone resistance heater for frozen storage room doors

Aluminum floor profile with resistance heaters for improved durability

Automatic Sliding Cold Room Door

The Automatic Sliding Cold Room Door is designed for high insulation performance, durability, and safe operation in industrial cold storage and food processing environments.

Technical Features

CTP composite door construction

Surface options: 1.5 mm AMB (antimicrobial) FRP, painted sheet metal, or stainless steel

EPDM rubber–based sealing system for maximum airtightness

Seamless exterior surface when 1.5 mm AMB (antimicrobial) FRP is used

Custom color options for the door leaf

Door leaf and frame manufactured from anodized aluminum, minimizing heat transfer

Door leaf insulated with high-pressure polyurethane injection (density: 42 kg/m³)

220V, 25 W/m silicone heater for frozen storage room applications

Reinforced aluminum floor profile with resistance heater

Automation & Safety Systems

Automatic opening system with pinion-connected rack and pinion mechanism

Photocell safety sensor preventing accidental entrapment

Remote-control operation for convenient access

Manual operation mode available in power failure or non-electrical environments

Automatic time-setting functions via digital control panel

High-Durability Sliding Door for Meat Processing & Slaughterhouse Monorail Systems

The Monorail Sliding Cold Room Door is engineered for industrial slaughterhouses and meat processing plants, providing excellent insulation, durability, and seamless compatibility with monorail carcass transfer systems.

Monorail Sliding Cold Room Door

Technical Features

FRP composite door construction

Surface options: 1.5 mm AMB (antimicrobial) FRP, painted sheet metal, or stainless steel

EPDM rubber–based gasket system

Custom color options for the door blade

Anodized aluminum door frame and blade to prevent heat transfer

Door blade insulated with high-pressure polyurethane injection (density: 42 kg/m³)

Monorail System Compatibility

Integrated monorail system on the door and frame

Polyamide protective cover for articulated monorail mechanisms

Stainless-steel rail profiles suitable for both fixed and articulated monorail lines

Seamless surface when using 1.5 mm AMB FRP

Reinforced structure for continuous heavy-duty operation

Key Advantages

Superior thermal insulation

Hygienic and easy-to-clean FRP surface

Shock-resistant and long-lasting structure

Designed for high-load, continuous monorail movement environments

HINGED DOOR

Anodized aluminum that prevents heat transfer for the door frame and blade

Door blade: 42 kg/m³ density high pressure polyurethane injection

1.5 mm AMB (antimicrobial) CTP, painted sheet or stainless surface

Desired color choice in door blade

Door lock that can be opened from inside (evenlocked)and outside

Rising and adjustable hinges

EPDM rubber system

220 volt, 25 w/m silicone based resistors on frozen storage doors

Door leaf and frame are made of anodized aluminum that prevents heat transfer.

Door leaf, high pressure polyurethane injection with a density of 42 kg/m³

1.5 mm AMB (antimicrobial) CTP, painted sheet metal or stainless surface

Desired color option on the door leaf

Door lock that can be opened from inside and outside

Rising type hinge

EPDM rubber based seal system

220 volt, 25 w/m silicon based resistance on frozen storage doors

DURABLE WITH ITS CTP COMPOSITE STRUCTURE

DURABLE WITH ITS CTP COMPOSITE STRUCTURE

Door leaf and frame are made of anodized aluminum that prevents heat transfer.

Door leaf, high pressure polyurethane injection with a density of 42 kg/m³

1.5 mm AMB (Antimicrobial) CTP, painted sheet metal or stainless surface

Desired color option on the door leaf

Door lock that can be opened from inside and outside

Rising type hinge

EPDM rubber based seal system

220 volt, 25 w/m silicon based resistance on frozen storage doors

Door frame is suitable for monorail system

Single wing fixed operation.

Door leaf and frame, anodized aluminum

Door leaf, high pressure polyurethane injection with a density of 42 kg/m³

1.5 mm AMB (antimicrobial) CTP, painted sheet metal or stainless surface

Desired color option on the door leaf

Rising type hinge

EPDM rubber based gasket system suitable for the wing profile

Plexiglass door leaf glasses with EPDM rubber seals

Hinged that can be opened in and out and fixed at 90º when necessary

Shock absorbing PVC protection tape